Our goal is constant growth

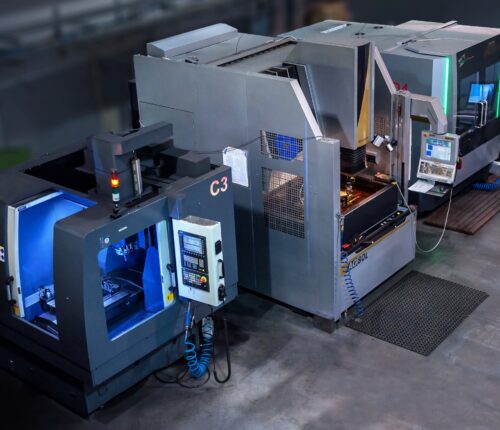

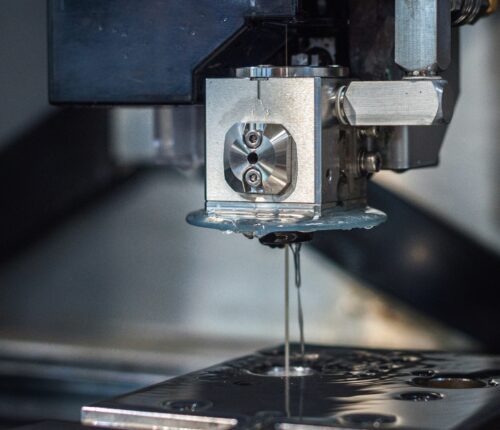

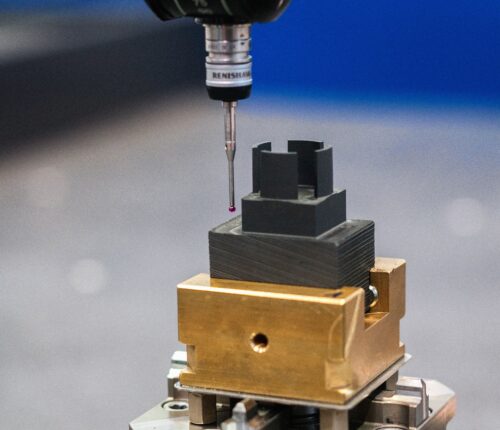

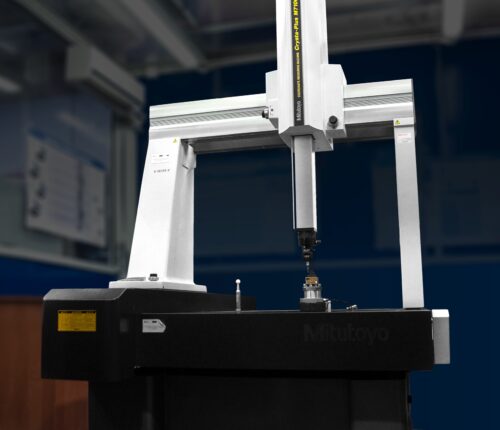

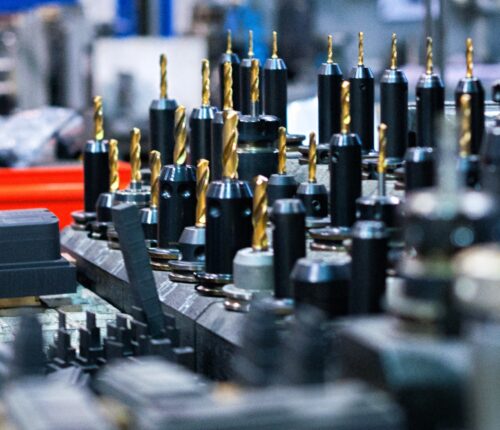

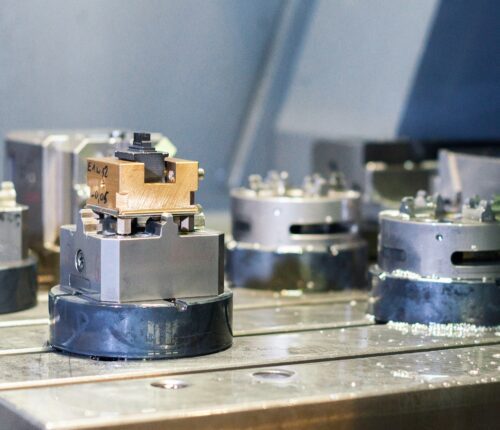

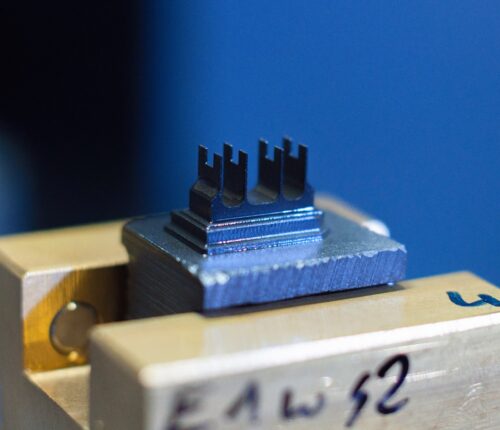

We execute injection mold projects from scratch, starting with the concept, through design, construction and mold creation stages, until the final product made of plastic. We restore injection molds with the use of the latest technologies, such as laser metal deposition, by utilizing CAD, CNC, CMM software and measuring machines for reverse engineering. Furthermore, our services include processing of atypical replacement parts for machines and devices. We are able to produce stamping and blanking dies, plug gauges, assembly machines, as well as specialized industrial equipment. If necessary, all these can be properly modified and fitted for a specific technological process.

Our products meet the highest visual and technical standards. When fulfilling production orders, we use both customer-provided molds and ones we create ourselves based on client specifications.